Polyacrylonitrile (PAN) Manufacturing Plant Project Report: A Comprehensive Guide

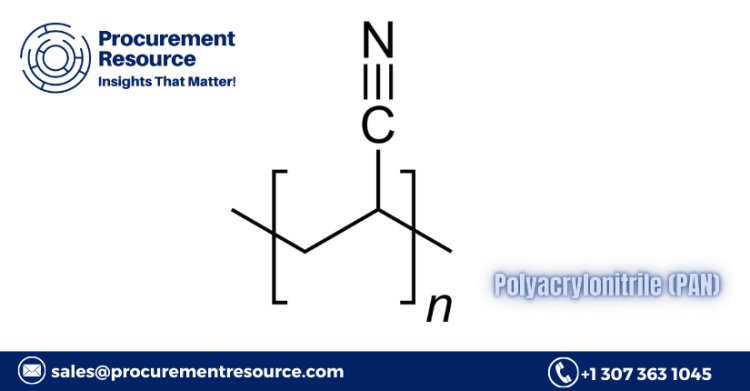

Polyacrylonitrile (PAN) is a crucial polymer used in the production of synthetic fibers, carbon fibers, and various other industrial applications.

Polyacrylonitrile (PAN) is a crucial polymer used in the production of synthetic fibers, carbon fibers, and various other industrial applications. The increasing demand for carbon fibers, particularly in automotive, aerospace, and construction industries, has made PAN a highly sought-after material. This has created ample opportunities for setting up Polyacrylonitrile (PAN) manufacturing plants to cater to the growing market. In this article, we will explore the key components of a Polyacrylonitrile (PAN) Manufacturing Plant Project Report, including market analysis, manufacturing process, procurement strategies, and growth potential.

Request a Free Sample – https://www.procurementresource.com/reports/polyacrylonitrile-pan-manufacturing-plant-project-report/request-sample

Market Overview and Demand Analysis

The demand for Polyacrylonitrile (PAN) has witnessed significant growth due to its versatility in applications, especially in the production of high-strength carbon fibers. Carbon fibers, which are derived from PAN, are in high demand across various industries due to their lightweight and high-performance characteristics. Industries such as aerospace, automotive, and energy are increasingly using carbon fibers for manufacturing lightweight components, which help in improving fuel efficiency, reducing emissions, and enhancing the strength-to-weight ratio.

In the textile industry, PAN is used to create fibers for clothing, home furnishings, and other textile products. The continuous growth in the demand for synthetic textiles is one of the driving factors for the production of PAN, as it offers better durability and resilience compared to natural fibers.

Read Full Report With Table Of Contents – https://www.procurementresource.com/reports/polyacrylonitrile-pan-manufacturing-plant-project-report/toc

Market analysis also indicates that the increasing need for sustainable materials is driving the demand for carbon fibers derived from PAN. Carbon fibers are being adopted in various applications for their energy efficiency and ability to replace metals, which further contributes to the rising need for PAN.

Regional Insights

Regional insights provide a deeper understanding of the demand and supply landscape of PAN manufacturing. North America and Europe are major producers and consumers of PAN, largely driven by the aerospace and automotive industries. The demand for lightweight materials in these sectors is a key driver for PAN consumption in these regions.

In Asia-Pacific, particularly in China and India, the demand for PAN is surging as industries such as automotive, construction, and textiles expand rapidly. As the manufacturing capabilities in these regions grow, PAN production is expected to increase, creating new opportunities for PAN manufacturing plants.

Emerging markets in South America and Africa are also showing increasing demand for PAN, as these regions invest in infrastructure projects, renewable energy, and automotive industries, which require the use of carbon fibers.

Manufacturing Process for Polyacrylonitrile (PAN)

The manufacturing process of Polyacrylonitrile (PAN) is a critical aspect of the overall PAN Manufacturing Plant Project Report. The process involves the polymerization of acrylonitrile monomers to produce PAN, which is a key precursor for carbon fiber production. The general steps involved in the production of PAN are as follows:

-

Polymerization – The first step in the process is the polymerization of acrylonitrile with other co-monomers to form polyacrylonitrile. This reaction typically takes place in an aqueous solution or suspension, using free-radical initiators under controlled temperature and pressure conditions.

-

Spinning – Once the PAN polymer is synthesized, it is extruded into fibers using the wet-spinning process. In this process, the PAN solution is extruded through spinnerets into a coagulating bath, where the fibers solidify and are drawn into long strands.

-

Stretching and Drawing – The PAN fibers are then stretched and drawn to align the polymer chains, which enhances the mechanical properties of the fibers. This step is critical for achieving the desired tensile strength and modulus in the final product.

-

Heat Treatment – After the fibers are drawn, they undergo heat treatment to stabilize the structure and remove impurities. This process, known as oxidation, prepares the fibers for carbonization, which is the next step in the production of carbon fibers.

-

Carbonization – The final step in the process involves the conversion of PAN fibers into carbon fibers through pyrolysis. The fibers are heated to extremely high temperatures (up to 1,500°C) in an inert atmosphere, which removes non-carbon elements and leaves behind pure carbon.

Equipment and Technology

The Polyacrylonitrile (PAN) manufacturing plant requires specialized equipment and technology to ensure high production efficiency and product quality. Some key equipment used in PAN manufacturing includes:

- Polymerization reactors – These are used to carry out the polymerization of acrylonitrile into PAN under controlled temperature and pressure conditions.

- Extrusion units – These are used for spinning PAN fibers from the polymer solution.

- Stretching machines – These machines stretch and draw the fibers to improve their mechanical properties.

- Carbonization furnaces – These furnaces are used for the high-temperature conversion of PAN fibers into carbon fibers.

- Quality control systems – These systems are essential for monitoring the properties of the fibers, ensuring that they meet the required standards for various applications.

Key Considerations for a PAN Manufacturing Plant

When setting up a Polyacrylonitrile (PAN) manufacturing plant, there are several key factors to consider:

-

Raw Material Supply – One of the most critical aspects of the manufacturing process is ensuring a consistent supply of high-quality acrylonitrile, which is the primary raw material for PAN production. Establishing reliable supply chains for raw materials is crucial to minimize production disruptions and maintain cost efficiency.

-

Energy Efficiency – The production of PAN and carbon fibers is an energy-intensive process. Implementing energy-efficient technologies and utilizing renewable energy sources can help reduce operational costs and improve the plant’s environmental footprint.

-

Environmental Regulations – Compliance with local environmental regulations is essential, as the production process can generate significant emissions. Adopting best practices for waste management and emissions control can help mitigate the environmental impact and ensure regulatory compliance.

-

Technological Advancements – Keeping up with the latest technological advancements in polymerization and carbonization can help improve production efficiency and product quality. Investing in cutting-edge equipment and automation systems can also reduce labor costs and improve the overall profitability of the plant.

Procurement Resource

Effectively managing procurement for a Polyacrylonitrile (PAN) manufacturing plant requires access to reliable resources. Procurement resources can help businesses track raw material prices, identify reliable suppliers, and monitor market trends.

Key procurement strategies include:

-

Raw Material Sourcing – As acrylonitrile is the primary raw material for PAN production, it’s essential to have reliable suppliers and a consistent supply chain. Procurement professionals can leverage databases and supplier networks to find cost-effective sources for raw materials.

-

Supplier Evaluation – Using procurement resources like supplier databases and performance metrics can help businesses evaluate potential suppliers based on factors like reliability, pricing, and delivery timelines.

-

Cost Management – By utilizing price databases and market intelligence tools, procurement teams can track fluctuations in raw material prices and adjust their purchasing strategies accordingly. This can help optimize purchasing decisions and reduce the impact of price volatility.

-

Contract Negotiation – Procurement resources also provide valuable insights into market trends, enabling businesses to negotiate better terms with suppliers and secure favorable long-term contracts for raw materials.

By leveraging procurement resources, businesses can ensure a smooth and cost-efficient supply chain, which is critical for the success of any PAN manufacturing plant project.

Contact Us

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: sales@procurementresource.com

Toll-Free Numbers:

USA: 1 307 363 1045

UK: 44 7537171117

Asia-Pacific (APAC): 91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA

What's Your Reaction?